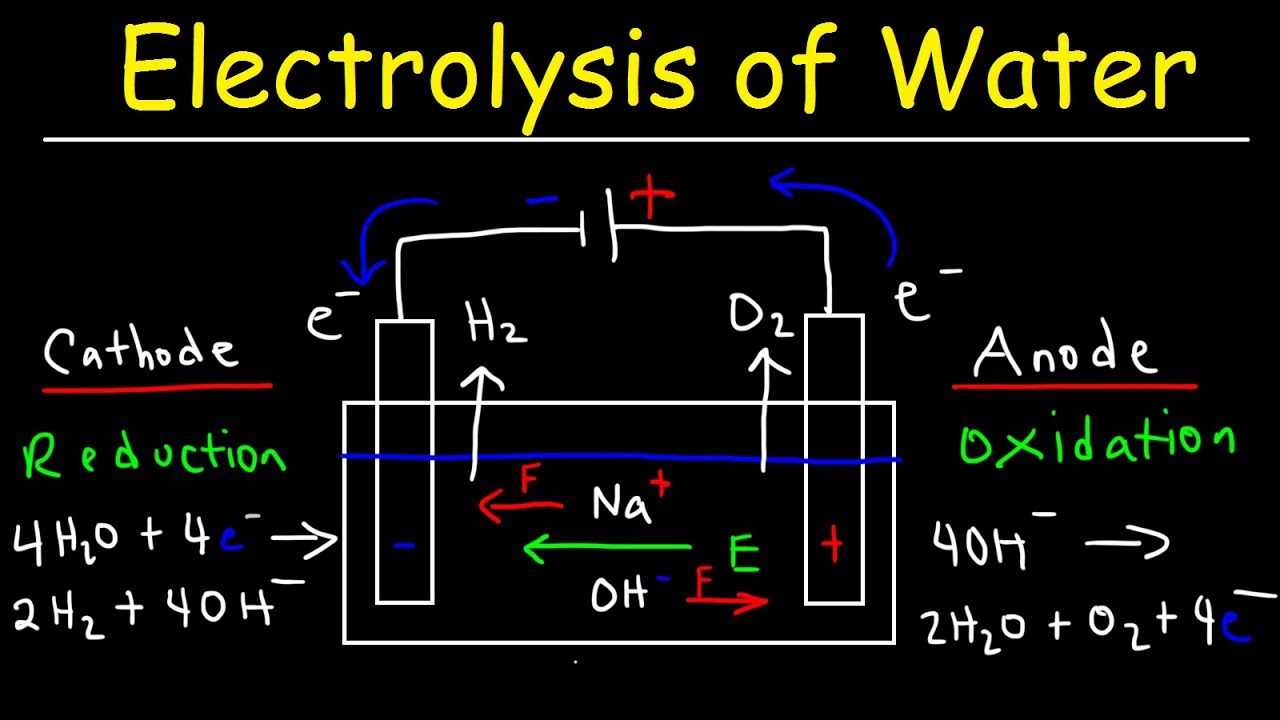

This is done in order to achieve useful current densities in the electrolyte despite its inherent electrical resistance. Īlthough theory predicts that a potential of a little over 4.07 volts should be sufficient to cause the reaction to go forward, in practice potentials of up to 8 volts are used. Perforated iron baffles are arranged in the cell to direct the products into separate chambers without their ever coming into contact with each other. If the electrolyte contained only calcium ions and no sodium, calcium metal would be produced as the cathode product (which indeed is how metallic calcium is produced).īoth the products of the electrolysis, sodium metal and chlorine gas, are less dense than the electrolyte and therefore float to the surface. Hence the sodium ions are reduced to metallic form in preference to those of calcium. The calcium does not enter into the reaction because its reduction potential of -2.87 volts is lower than that of sodium, which is -2.38 volts. Therefore, one option is to have a NaCl (42%) and CaCl 2 (58%) mixture. If pure sodium chloride is used, a metallic sodium emulsion is formed in the molten NaCl which is impossible to separate. Sodium chloride (NaCl) melts at 801 ☌ (1074 Kelvin), but a salt mixture can be kept liquid at a temperature as low as 600 ☌ at the mixture containing, by weight: 33.2% NaCl and 66.8% CaCl 2. Some calcium chloride and/or chlorides of barium (BaCl 2) and strontium (SrCl 2), and, in some processes, sodium fluoride (NaF) are added to the electrolyte to reduce the temperature required to keep the electrolyte liquid. Although solid sodium chloride is a poor conductor of electricity, when molten the sodium and chloride ions are mobilized, which become charge carriers and allow conduction of electric current. The electrolyte is sodium chloride that has been heated to the liquid state. The Downs cell uses a carbon anode and an iron cathode. The Downs cell was invented in 1923 (patented: 1924) by the American chemist James Cloyd Downs (1885–1957). Diagram of a downs cell electrolyzing molten NaCl into chlorine gas and sodium metalĭowns' process is an electrochemical method for the commercial preparation of metallic sodium, in which molten NaCl is electrolyzed in a special apparatus called the Downs cell.

0 kommentar(er)

0 kommentar(er)